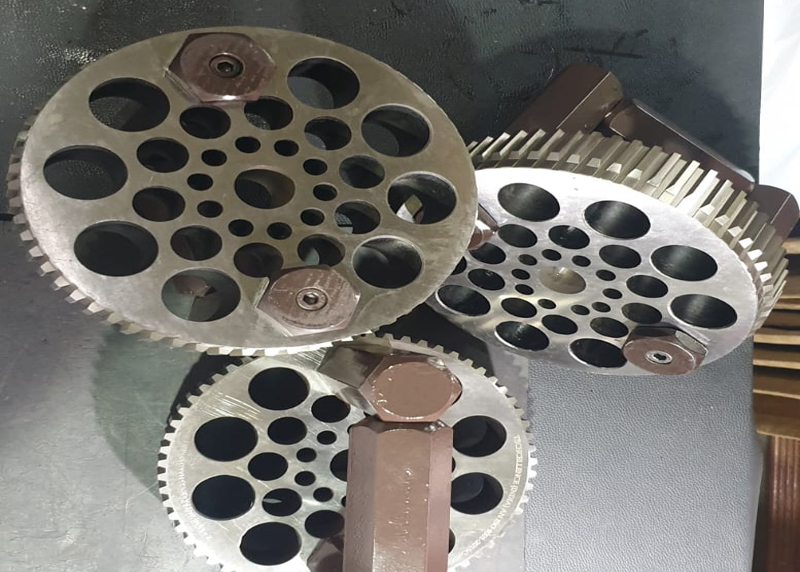

Spline Mandrels

Spline Mandrels

Involute, Parallel & Serration

Splined Mandrels are used for the inspection of the concentricity of an internal spline relative to another component feature which is used to check the run out of the component.

The mandrel has tapered teeth for side fits splines or tapered major diameter for major diameter fit splines

Always the mandrel is used after the broaching of a component has been done.

Spline also have the capabilities to produce Straight or Helical Tapered Mandrels to suit customers exact requirements.

Involute Spline mandrels checks the Splined Components on Pitch Circle Diameter of Splines or on the Major Diameter of internal splines, serrations or involute splines and phase run outs with respect to spline in components. The component checks the accuracies like face run out, OD run out with respect to PCD or major diameter. Spline Mandrels are invariably employed for finishing machining operations PCD or major dia..

Involute Spline Mandrels types:

- Taper Hobbing Mandrels

- Taper Mandrels

- Run out Checking Mandrels.

- Major Diameter : 10 mm - 250 mm

- Module : 0.5 Module - 10 Module

- Pressure Angle (PA) : 14.5°, 20°, 25°, 30°, 37.5°, 45°, PA or as per customer requirement.

- Number of Splines : As specified

Splines Profile Range:

- Involute, Straight, Round, Helical, Serrations, Special profiles

Quality Standard:

- Involute Spline ANSI B 92 JIS, DIN 5480, 5482, HES etc.

SURFACE COATING: (OPTIONAL)

- Available in TiN, ALTIN, ALCRONA Coatings

Material:

- SAE O1/O2 OHNS for high stability, HSS M2, POWDER METALLURGY STEEL

Quality - Complete Customer Satisfaction (CCS)

At Yash International, we believe in 3-sigma quality process

- 1 Maintaining World-class quality products & ensuring deliveries on-time

- 2 Providing most cost-effective pricing to our clients

- 3 Always ensuring complete customer satisfaction (CCS)

You will see technology at its best, be it in the components, the advanced production line or the well trained work force. We adhere to the exacting AGMA, DIN, BS, and JIS industry standards to maintain accuracies and preserve precise tolerances To maintain the best quality of the products we have adopted system of mandatory inspection and tests as well as periodic quality audits and system evaluations.

Certifications

We are a ISO 9001:2015 Certified company driven by Professional excellence, Technical competence and Total Quality Management system

MSME REGISTRATION (GOVT OF INDIA) CERTIFICATION\

REGISTERED MEMBER OF FEDERATION OF INDIAN EXPORTS ORGANIZATION (FIEO)

We, Commit ourselves for supplying products that would give complete satisfaction to customer. We will strive to achieve growth and leading position in the market by; supplying consistent quality products to our valued customers.

Get a Free Quote

Yash International

A-291/1,Okhla Industrial Area

Phase-I New Delhi -110020 (India)

A-291/1,Okhla Industrial Area

Phase-I New Delhi -110020 (India) Tel-+91-11-26812754,

Tel-+91-11-26812754,

+91-9811199390 sales@yashtools.com,

sales@yashtools.com,

yashinternational02@gmail.com